People-Centric Triple Safety Environment

As a large-scale comprehensive construction company operating in a complex and ever-changing environment, we are committed to creating a sustainable environment and fulfilling our social responsibilities. We view construction safety, quality management, and environmental protection as being of he highest priority. Guided by the principles of safety and professional innovation, we engage all team members in continuous improvement. We maintain ecological environments, develop technological disaster prevention measures, strengthen risk management in construction planning and execution, enhance hazard awareness, and establish effective communication mechanisms. Our people-centric approach aims to provide all employees with a triple-safe employment environment: “safe job, safe workplace, and labor safety”.

After being signed off by the Chairman, BES’s policies for safety, health, and environmental protection are announced and effectively implemented throughout the entire organization.

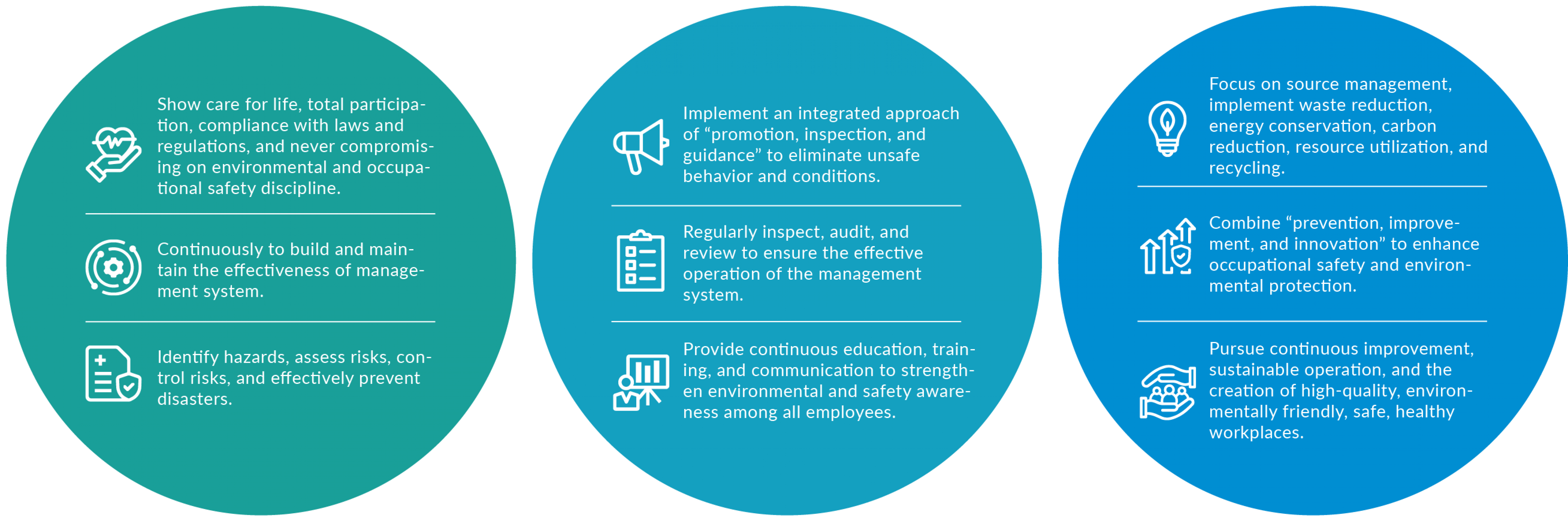

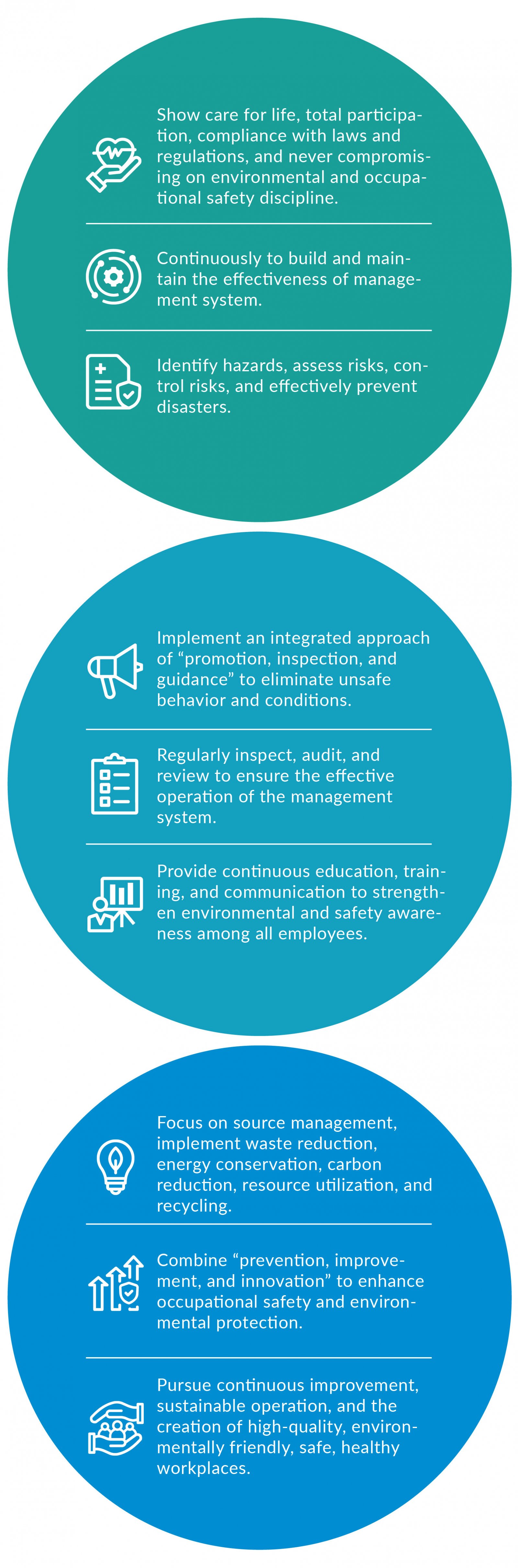

Our principles of safety, health, and environmental protection management are as follows:

Company Policy Documents

Actions to Ensure Environmental Protection and Quality Management

The Occupational Safety & Health Management Office conducts monthly on-site (20), online (20), and joint (3) inspections. Company supervisors also perform periodic checks at construction sites.

*Recent occupational safety and health statistics:

|

Year |

2021 |

2022 |

|

Number of Fatalities |

0 |

0 |

|

Number of Occupational Accidents |

2 |

0 |

|

Lost Days |

184 |

0 |

|

Total Work Hours (BES) |

1,731,496 |

1,618,706 |

|

Total Work Hours (Contractors) |

2,981,219 |

1,849,492 |

|

Total Working Hours (BES + Contractors) |

4,712,715 |

3,468,198 |

|

BES Incidence Rate (Frequency Rate of Disabling Injuries FR) |

1.15 | 0.00 |

|

BES Severe Injury Ratio (Severe Rate of Disabling Injuries SR) |

106 | 0 |

|

BES Injury Index (FSI - Frequency-Severity Index) |

0.34 | 0.00 |

Greenhouse gas management strategy, methods, and objectives:

1. Establish procedures for greenhouse gas inventory management and internal verification and management audit procedures as inventory standards.

2. The general manager signs the greenhouse gas inventory and voluntary reduction declaration, and appoints the chairman of the greenhouse gas inventory implementation team.

3. Form the greenhouse gas inventory implementation team to conduct inventory operations across departments.

4. Conduct internal verification according to the greenhouse gas inventory list, report, and procedures, and make improvements to any shortcomings.

5. Perform external verification and obtain a reasonable assurance statement.

6. Convene the management review committee to review the strategy for improving greenhouse gas inventory shortcomings, and submit the inventory results to the ESG committee to develop carbon reduction strategies.

*Greenhouse gas emissions and intensity statistics:

|

Year |

2021 |

2022 |

|

Direct greenhouse gas emissions (metric tons CO2e) |

754.763 |

1104.1034 |

|

Energy indirect greenhouse gas emissions (metric tons CO2e) |

3643.9018 |

4164.0083 |

|

Other indirect greenhouse gas emissions (metric tons CO2e) |

Excluded |

Excluded |

|

Total greenhouse gas emissions (metric tons CO2e) |

4398.665 |

5268.112 |

|

Greenhouse gas emission intensity (metric tons CO2e per million of operating revenue) |

0.2780 |

0.3795 |

|

Data boundary: |

Parent company |

Parent company |

|

Verification obtained |

Yes (headquarters) |

Yes (entire company) |

Greenhouse Gas Emission Verification for year 2021

Greenhouse Gas Emission Verification for year 2022

*Water and waste statistics:

|

Year |

2021 |

2022 |

|

Water consumption (tons) |

287802 |

106228 |

|

Water intensity (tons per million of operating revenue) |

18.1880 |

7.6514 |

|

Total weight of general waste (tons) |

2,046.080 |

34943.45 |

|

Total weight of hazardous waste (tons) |

734.640 |

8.005 |

|

Waste intensity (tons per million of operating revenue) |

0.2003 |

2.5175 |

As part of our systematic approach to maintan safety, health, environmental protection, and quality management, BES adheres to relevant government regulations and international standards. We have obtained certifications for relevant management systems to strengthen, promote, and continually improve occupational safety, environmental protection, and quality management practices

Certification Standards Obtained by BES (click the hyperlink to view):

ISO 45001:2018 Occupational Health and Safety Management System

CNS 45001:2018 Occupational Health and Safety Management System

ISO 14001:2015 Environmental Management System

ISO 9001:2015 Quality Management System

Collaborating with Suppliers for Safety and Environmental Protection

Explore how we collaborate with suppliers to promote relevant initiatives

Preferential treatment for suppliers rated as excellent

To ensure suppliers’ progress, safety, health, and environmental protection comply with BES standards, we have established the “Supplier Assessment Operation Guidelines”. Suppliers rated as excellent will receive benefits such as reduced bid bonds and performance guarantees. Suppliers rated as unsatisfactory will be included in the list of blacklisted suppliers.

The annual supplier assessment conference is presided over by the President. The results of the supplier assessment for the past two years are as follows:

|

Year |

Excellent Suppliers |

Qualified Suppliers |

Unsatisfactory Suppliers |

Total |

|

111 |

98 |

299 |

2 |

399 |

|

112 |

72 |

302 |

6 |

380 |

People-Centric Triple Safety Environment

As a large-scale comprehensive construction company operating in a complex and ever-changing environment, we are committed to creating a sustainable environment and fulfilling our social responsibilities. We view construction safety, quality management, and environmental protection as being of he highest priority. Guided by the principles of safety and professional innovation, we engage all team members in continuous improvement. We maintain ecological environments, develop technological disaster prevention measures, strengthen risk management in construction planning and execution, enhance hazard awareness, and establish effective communication mechanisms. Our people-centric approach aims to provide all employees with a triple-safe employment environment: “safe job, safe workplace, and labor safety”.

After being signed off by the Chairman, BES’s policies for safety, health, and environmental protection are announced and effectively implemented throughout the entire organization.

Our principles of safety, health, and environmental protection management are as follows:

Company Policy Documents

Actions to Ensure Environmental Protection and Quality Management

The Occupational Safety & Health Management Office conducts monthly on-site (20), online (20), and joint (3) inspections. Company supervisors also perform periodic checks at construction sites.

*Recent occupational safety and health statistics:

|

Year |

2021 |

2022 |

|

Number of Fatalities |

0 |

0 |

|

Number of Occupational Accidents |

2 |

0 |

|

Lost Days |

184 |

0 |

|

Total Work Hours (BES) |

1,731,496 |

1,618,706 |

|

Total Work Hours (Contractors) |

2,981,219 |

1,849,492 |

|

Total Working Hours (BES + Contractors) |

4,712,715 |

3,468,198 |

|

BES Incidence Rate (Frequency Rate of Disabling Injuries FR) |

1.15 |

0.00 |

|

BES Severe Injury Ratio (Severe Rate of Disabling Injuries SR) |

106 |

0 |

|

BES Injury Index (FSI - Frequency-Severity Index) |

0.34 |

0.00 |

Greenhouse gas management strategy, methods, and objectives:

1. Establish procedures for greenhouse gas inventory management and internal verification and management audit procedures as inventory standards.

2. The general manager signs the greenhouse gas inventory and voluntary reduction declaration, and appoints the chairman of the greenhouse gas inventory implementation team.

3. Form the greenhouse gas inventory implementation team to conduct inventory operations across departments.

4. Conduct internal verification according to the greenhouse gas inventory list, report, and procedures, and make improvements to any shortcomings.

5. Perform external verification and obtain a reasonable assurance statement.

6. Convene the management review committee to review the strategy for improving greenhouse gas inventory shortcomings, and submit the inventory results to the ESG committee to develop carbon reduction strategies.

*Greenhouse gas emissions and intensity statistics:

|

Year |

2021 |

2022 |

|

Direct greenhouse gas emissions (metric tons CO2e) |

754.763 |

1104.1034 |

|

Energy indirect greenhouse gas emissions (metric tons CO2e) |

3643.9018 |

4164.0083 |

|

Other indirect greenhouse gas emissions (metric tons CO2e) |

Excluded |

Excluded |

|

Total greenhouse gas emissions (metric tons CO2e) |

4398.665 |

5268.112 |

|

Greenhouse gas emission intensity (metric tons CO2e per million of operating revenue) |

0.2780 |

0.3795 |

|

Data boundary: |

Parent company |

Parent company |

|

Verification obtained |

Yes (headquarters) |

Yes (entire company) |

Greenhouse Gas Emission Verification for year 2021

Greenhouse Gas Emission Verification for year 2022

*Water and waste statistics:

|

Year |

2021 |

2022 |

|

Water consumption (tons) |

287802 |

106228 |

|

Water intensity (tons per million of operating revenue) |

18.1880 |

7.6514 |

|

Total weight of general waste (tons) |

2,046.080 |

34943.45 |

|

Total weight of hazardous waste (tons) |

734.640 |

8.005 |

|

Waste intensity (tons per million of operating revenue) |

0.2003 |

2.5175 |

As part of our systematic approach to maintan safety, health, environmental protection, and quality management, BES adheres to relevant government regulations and international standards. We have obtained certifications for relevant management systems to strengthen, promote, and continually improve occupational safety, environmental protection, and quality management practices

Certification Standards Obtained by BES (click the hyperlink to view):

ISO 45001:2018 Occupational Health and Safety Management System

CNS 45001:2018 Occupational Health and Safety Management System

ISO 14001:2015 Environmental Management System

ISO 9001:2015 Quality Management System

Collaborating with Suppliers for Safety and Environmental Protection

Explore how we collaborate with suppliers to promote relevant initiatives

Preferential treatment for suppliers rated as excellent

To ensure suppliers’ progress, safety, health, and environmental protection comply with BES standards, we have established the “Supplier Assessment Operation Guidelines”. Suppliers rated as excellent will receive benefits such as reduced bid bonds and performance guarantees. Suppliers rated as unsatisfactory will be included in the list of blacklisted suppliers.

The annual supplier assessment conference is presided over by the President. The results of the supplier assessment for the past two years are as follows:

|

Year |

Excellent Suppliers |

Qualified Suppliers |

Unsatisfactory Suppliers |

Total |

|

111 |

98 |

299 |

2 |

399 |

|

112 |

72 |

302 |

6 |

380 |